(1):PET products application

Leading PET products

PET is applicable to electronic, electrical and automobile industry, various coil formers, transformers, TV sets, audio-recorder spare parts and housings, auto lampholders, lampshades, incandescent lamp holders, relays, selenium rectifiers and etc. The application percentage of PET engineering plastics at present: 26% in electronics and electrical appliances, 22% in automobiles, 19% in machinery, 10% in utensils, 10% in consumer goods and 13% in others.

Leading PET products: PET bottle, PET resin for water vapour bottle, PET resin for oil bottle, PET resin bottle for carbonated beverage, package PET resin bottle for industrial purpose.

Item |

Unit |

Grade |

TH101 |

TH102 |

TH102B |

TH

102C |

TH103 |

TH104 |

TH105 |

TH106 |

Application |

Water

Bottle |

Water

Bottle |

Water

Bottle |

Gas Water

Bottle |

Oil

bottle |

Carbonated

Beverage Bottle |

Hot

Filling

Bottle |

Industrial

packages |

Test

Method |

first

class |

first

class |

first

class |

first

class |

first

class |

first

class |

first

class |

first

class |

Intrinsic

Viscosity |

Dl/g |

ASTM

D4603 (

30℃) |

0.740±0.02 |

0.800±0.02 |

M0±0.02 |

0.820±0.02 |

0.840±0.02 |

0.870±0.02 |

0.765±0.02 |

M1±0.02 |

Color (L) |

- |

GB/T14190-1993 |

84±3 |

84±3 |

84±3 |

84±3 |

84±3 |

84±3 |

84±3 |

≥80 |

Color (B) |

- |

≤1.5 |

≤1.5 |

≤1.5 |

≤1.5 |

≤1.5 |

≤1.5 |

≤1.5 |

≤3.0 |

Melting

Point |

℃ |

GB/T17931-1999DSC |

248±2 |

248±2 |

M2±2 |

247±2 |

246±2 |

249±2 |

252±2 |

M3±4 |

Content

of

Acetaldehyde |

mg/kg |

GB/T17931-1999 |

≤1.0 |

≤1.0 |

≤1.0 |

≤1.0 |

≤1.0 |

≤1.0 |

≤1.0 |

- |

Density |

g/cm3 |

GB/T17931-1999 |

1.40±0.01 |

1.40±0.01 |

1.40±0.01 |

1.40±0.01 |

1.40±0.01 |

1.40±0.01 |

1.40±0.01 |

1.40±0.01 |

Carboxyl

End Group |

mol/t |

GB/T17931-1999 |

≤35 |

≤35 |

≤35 |

≤35 |

≤35 |

≤35 |

≤35 |

≤50 |

Ash

Content |

% |

GB/T9345-1988 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

Powder |

mg/kg |

GB/T14190-1993 |

≤50 |

≤50 |

≤50 |

≤50 |

≤50 |

≤50 |

≤50 |

≤50 |

Water

Content |

% |

GB/T14190-1993 |

≤0.3 |

≤0.3 |

≤0.3 |

≤0.3 |

≤0.3 |

≤0.3 |

≤0.3 |

≤0.3 |

Weight of

100 Chips |

gl |

- |

1.7±0.2 |

1.7±0.2 |

1.7±0.2 |

1.7±0.2 |

1.7±0.2 |

1.7±0.2 |

1.7±0.2 |

1.7±0.2 |

DEG |

% |

GB/T14190-1993 |

1.3±0.2 |

1.3±0.2 |

1.3±0.2 |

1.3±0.2 |

1.3±0.2 |

1.1±0.2 |

1.1±0.2 |

≤1.5 |

(2)PBT products application

PBT products

PBT is a kind of thermoplastics and has advantages of heat resistance, weather resistance, resistance chemical reagents, optimum electrical characteristics, little moisture pick-up and more shine. It’s widely used in electronics and electrical equipment, auto accessories, machineries, household apparatus; PBT along with PPS, PC, POM and PA are categorized as five major extensively-used engineering plastics.

The company’s proprietary, high value-added and high-tech products like chips for bottles of carbonated beverage, water, water vapor, hot filled beverage, edible oil and PBT are in the forefront in terms of quality in the same industry nationwide and win many honors from the state and the Autonomous Region.

Automobile, electrical and electronic industry:

Due to the good processable properties of PBT, a large number of PBT modification technologies are researched and developed at home and abroad. Using nanotechnology, composite technology, polymer alloy and other measures, we can improve the impact resistance, flowability, flame retardant properties of PBT and its compounded products are mainly used for automobile parts, electrical and electronic components as well as decoration items in the car, household electrical appliance housing, more energy, more energy-efficient and more environment-friendly.

Textile industry:

PBT fiber is a kind of polyester fiber, it has the characteristics of high elasticity. Compared with other fiber, softness of PBT filament is better, more easy to process, better elongation and better dyeability , not easily deformed, not easy to be oxidized. In addition to the traditional application in elastic jeans, bathrobe, sportswear, more suitable for making special dress materials or high elastic yarn used for clothing.

Film packaging field:

After the technological transformation, PBT also can be used for film packaging industry, with properties of heat-resistance and resistance to moisture, more extensive application has been foreseen.

(3)Biodegradable Resin PBAT/PBS

As a subsidiary company of Xinjiang Blue Ridge Tunhe Chemical, Xinjiang Blue Ridge Tunhe Polyester Co., Ltd is an innovative company, relying on the advantages of Xinjiang’s local plentiful natural resources, boasting of the most advanced production facilities in the industry and concept of green development. The company is dedicated to producing biodegradable and compostable resin PBAT and PBS with current capacity 130000mt per year, and 240,000 tons of production capacity is under construction and it is expected to be officially launched by the end of October 2022.. Thanks to the cooperation with Tsinghua University to get cutting- edge continuous production technology and our 21 years of polymerization experience in polyester industry, the quality of our PBAT and PBS are widely recognized by customers around the world.

Tunhe’s PBAT and PBS are completely compostable according to various international standards and regulations like European standard EN 13432 and American Standard ASTM 6400, which will be eventually biodegraded to carbon dioxide, water and biomass when metabolized in the soil or compostable under standard conditions. Our resins are also certified by Ok Compost, BPI, ABAM, JBPA, FDA, EU Food Contact regulations, etc.

Compared with other biodegradable plastics, PBAT and PBS have excellent mechanical performance, almost same as PP and ABS, good heat resistance and outstanding processability allow it to be variously processed on conventional blown film plants, it is the best biodegradable plastic in terms of processability in current market and can be blended with a great quantity of calcium carbonate and starch etc. to produce cost effective products.

PBAT

Poly(butylene adipate-co-terephthalate)

Grade:TH801T

Molecular formula:H-(O-(CH2)4-O-CO-(CH2)4-CO-)n-(O-(CH2)4-O-CO-C6H4-CO-)m-H

CAS NO:55231-08-8

Color:Natural white

Raw material:BDO (1,4-butanediol), PTA (terephthalic acid)

Adipic Acid

Application:Film bags

mulching films paper coating

labels

3D printing

other packaging materials

Technical Data:

Storage:

Temperatures during transportation and storage should not exceed 70 oC. Keep resin in dry and ventilated warehouse to prevent moisture. Avoid contacting with soil, water and sludge, and no exposure to direct sunlight and extreme temperature. The maximum shelf life is 2 years in ambient temperature of 23oC if the package has been tightly sealed.

Drying:

It is recommended to pre-dry the material prior to getting the best processing performance. If the moisture of the resin is

less than 0.05% pre-drying may not be needed. Typical drying conditions:2 hours at 80oC (175oF).

PBS

Polybutylene succinate

Grade:TH803S

Molecular Formula:HO-(CO-(CH2)2-CO-O-(CH2)4-O)n-H

CAS NO:25777-14-4

Color:Naturalwhite

Raw Material:BDO (1,4-butanediol) SuccinicAcid

Application:injection molding tablewares and cutlery textile, fishing net, engineering components medical applications. etc

Technical Data:

Storage:

Temperatures during transportation and storage should not exceed 70 oC. Keep resin in dry and ventilated warehouse to prevent moisture. Avoid contacting with soil, water and sludge, and no exposure to direct sunlight and extreme temperature.The maximum shelf life is 2 years in ambient temperature of 23oC if the package has been tightly sealed.

Drying:

It is recommended to pre-dry the material prior to getting the best processing performance. If the moisture of the resin is less than 0.05% pre-drying may not be needed. Typical drying conditions:2 hours at 80oC (175oF).

PBSA

Grade:TH802

Color: Natural white

Raw material:BDO, succinic acid, adipic acid

Application:Sheet extrusion and other extrusion

Technical Data:

BIO-BASED PBST

Grade:TH901T

Color: Natural white

Raw material:BDO ( 1,4-butanediol), PTA (terephthalic acid), Bio Based Sebacic Acid

Application:shopping bags, mulching films, paper coating,Labels, Other packaging Materials

Technical Data:

BIO-BASED PBS

Grade:TH803S

Molecular Formula:HO-(CO-(CH2)2-CO-O-(CH2)4-O)n-H

CAS NO:25777-14-4

Color:Natural white

Raw material:BDO, succinic acid

Application:injection molding, tableware and cutlery, textile, fishing net, coffee capsule, engineering components,medical applications, etc.

Technical Data:

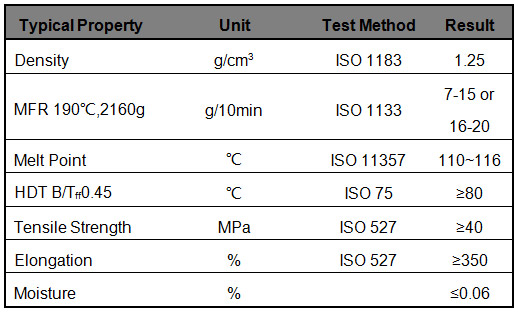

(4)TPEE

Brief introduction of product

TPEE (Thermoplastic Polyester Elastomer) is block copolymer which contains polyester hard segment and polyether soft segment. TPEEhas elasticity of the rubber and strength of the engineering plastics. Soft segment gives it elasticity and makes it like rubber. Hard segment gives it processing performance and makes it like plastic. Compared with rubber, it has better processing performance and longer service life. Compared with the engineering material, it also has the characteristic of high strength.

It is mainly used in the production of Automotive components ,Footwear, Electronics, food packages, Commercial manufacture and others.

TPEE processing technology and matters that need attention

As the hardness of TPEE increases, its high-temperature resistance, resilience, friction resistance, tensile strength, flexural modulus, crystallization rate and chemical resistance increase.

As the hardness of TPEE decreases, its low temperature resistance, elasticity, creep resistance, fatigue resistance, impact resistance and soft hand feel gradually improve.

Contacts:

Department Manager:

Mr. Michael Ma,

Mob: +86-18699400676,

Email: maxirong@lanshantunhe.com

European and Australian Sales:

Ms. Renne Zhao, Mob: +86-15999155218, Email: zhaojie@lanshantunhe.com

Ms. Liz Lay, Mob: +86-13629956974, Email: leizixian@lanshantunhe.com

Asian and American Sales:

Ms. He Yun, Mob: +86-13699970285, Email: heyun@lanshantunhe.com

|